Industrial and warehouse automation

Key solutions

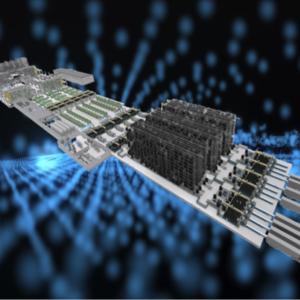

CIMCORP DREAM FACTORY

Tire plants automation

A complete solution, Dream Factory comprises a physical network of interconnected hardware and a cyber network that ties everything together electronically. The entire material flow – from the mixing machines to the nished tire warehouse – is controlled by Cimcorp’s Warehouse Control System (WCS), while the tracing of production data, recipe management and reporting are taken care of by Cimcorp’s Manufacturing Execution System (MES), enabling 100 per cent traceability of tires.

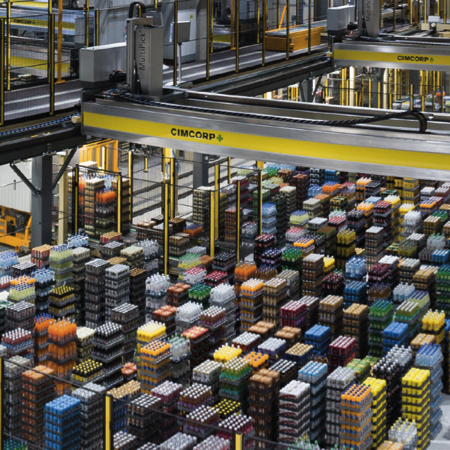

CIMCORP warehouse

and distribution automation

Cimcorp’s solutions are designed to meet the modern demands of distribution, including shorter lead times, SKU proliferation and challenging seasonal peaks amid labor shortages. We have developed unique order fulfillment and storage solutions for the food and beverage, retail, e-commerce, fast-moving consumer goods (FMCG) and postal services industries.

Our picking systems can handle a large variety of plastic crates, trays, totes, dollies and corrugated cases. With flexibility in mind, our modular approach means we can automate an entire distribution center or develop “islands of automation” integrated within manual operations—with the ability to scale up the levels of automation based on current business needs.

Automated Guided Vehicles (AGV)

AGVE offers 8 standard vehicles with a wide range of material handling capabilities. In addition to standard vehicles, AGVE has unique experience in providing completely customized AGVs. AGVE has over 100 custom mechanical AGV designs for payloads from 3kg up to 65 tons and lifting heights up to 11 meters. Most customized trucks are based on the standard models and all AGVs can use and combine any type of navigation available on the market. The model is chosen based on the weight of the load, size of the space, lifting height, and is not specifically linked to a given industry or method of navigation.

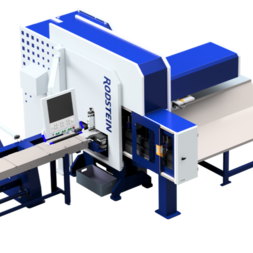

Automation of busbar production

Rodstein is a supplier of the world’s most efficient busbar manufacturing technologies. The servo-electric solutions challenge hydraulic machines, with outstanding energy efficiency and production speed, with automatic tool-change options simply not available elsewhere in the market.

Lifting Machinery

LiftMac is a new kind of tool for lifting four-loop big bags in industry, farming and infrastructure (like harbors etc).

By using this new generation tool the tele lifter driver does not need an assistant to attach/detach the big bags to the lifter or the driver does not need to step out from the cabin to do it by himself. This makes your logistic chain more effective, cost efficient and safe.